Steel drums are cylinder-shaped barrels widely used in a variety of commercial and industrial settings due to their adaptability and durability. Steel drums are affordable and reusable. They are ideal for meeting a variety of industrial transportation and storage demands. They can be found in storage facilities and transportation hubs worldwide, where they store a variety of industrial commodities, from food to dangerous chemicals. Large volumes of commercial liquids, such as lubricants, chemicals, or foodstuffs, can be stored in steel drums. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

We specialize in providing high-quality industrial packaging solutions, with a strong focus on 55-gallon drums for a wide range of applications. As a trusted partner in the packaging industry, we offer durable and reliable containers that meet the needs of various sectors, including chemicals, food processing, pharmaceuticals, and manufacturing. Our drums are designed for superior performance,...

We at Inmark, Inc. specialize in providing high-quality 55-gallon drums designed to meet the diverse storage and transportation needs of various industries. Our extensive expertise in industrial packaging allows us to offer solutions that prioritize durability, compliance, and efficiency. Whether handling hazardous materials, food-grade products, or general industrial goods, we ensure that our...

At Krook Container, Inc., we specialize in providing high-quality 55-gallon drums designed to meet the diverse needs of industries ranging from manufacturing and chemical processing to food and pharmaceuticals. Our extensive selection includes steel, plastic, and fiber drums, each engineered for durability, reliability, and compliance with industry standards.

More Steel Drum Manufacturers

The conventional steel drum typically has a storage space of 210 liters (@220 quarts) and is made of either stainless steel or carbon steel. Steel drums come in two basic varieties, open-head and tight-head. Open-head barrels feature removable covers; tight-head barrels have sealed covers and the only access to the contents held within are through a plug. Both can be equipped with various valves and accessories to broaden their utility and improve the effectiveness of emptying and filling.

Roll Forming

Steel drums may be created from various grades of steel. Regardless of which steel is used, steel drums are often created using roll forming to create components before being welded together. Metal sheets are forced into curved forms during roll forming by roller and die pairs. The roll-forming machine's rollers bend the sheets along their linear axis as they are passed through it. These curved sheets are then welded together at one or both ends and additionally welded around the drum's base, halfway up from the bottom and halfway down from the top, to provide additional strength.

Plastic Forming

Steel drum manufacture may also be done using the plastic forming technique. In plastic forming (also referred to as stamping), metals are pressed into a die to form desired shapes- in this case, curved sheets. This process relies on a metal’s plasticity, or ability to be bent into desired shapes. The plastic-forming procedure produces workpieces of excellent quality and high strength. This technique offers high output and minimal material use.

Welding

After the components of a drum body are formed, they are typically joined together with a seam welding machine. Seam welding uses electrode wheels (or roller electrodes) to produce a continuous seam at the intersection of both halves of a drum body. The process is mainly automatic. The metal is melted as it moves between the electrodes. Semi-molten surfaces are then pressed together, resulting in a consistently welded structure. The structure is subsequently cooled through a water-cooling process. Seam welding creates an incredibly strong weld for steel drum bodies.

Coating and Painting

Steel drums are usually coated and/or painted after being formed to provide aesthetic appeal and, more importantly, corrosion resistance. Steel drums are cleaned after forming and welding operations are finished and before coating and painting is performed. Using today’s technology, the coating/painting process is an automatic process.

The process begins with conveyors moving the drums through an area where they receive their first coating of paint. These barrels are then moved to a curing oven where they are dried based on a predetermined time and temperature. The barrels subsequently experience flash-off (drying) time based on the selected paint before they are coated a second time with paint or another coating material. The steel drums are dried and printed on after completion.

Considerations for Steel Drums

One should carefully consider the grade of steel, type of steel, their intended use, and other factors before selecting a specific steel drum. As an illustration, certain drums lack UN certification, while others can have weaker linings. The kind of steel utilized in production has a significant influence. Stainless steel and carbon steel are the two most popular types. Most industrial applications favor stainless steel because it provides a stronger galvanized and protective covering than carbon steel. Since they are less likely to rust and become contaminated, stainless steel barrels are far more durable and long-lasting.

Open Head Steel Drums

Steel drums with open heads get their name from the large hole at the top of the drum. Due to the ability to entirely remove and replace the lid as needed, open-head drums may also be called open-top drums. Steel clamps can be used to securely and safely fasten open-head drums, and they are simple to fill with liquids. When open head steel drums are being stored or transported, they can be equipped with tamper-evident components. However, open-head drums have the drawback that they are more likely to leak and spill if the lid is destroyed.

Tight Head Steel Drum

Steel drums with tight heads are unique in that the head of the drum does not have a detachable cover or wide hole to fill or access the contents within. The comparatively small access holes on tight-head drums are closed off with an industrial bung (stopper or plug). Steel drums with tight heads are significantly safer than those with open heads, but they are also more challenging to fill and empty. As long as the holes have a discharge outlet on the bottom of the barrel, they can be equipped with taps to make emptying easier.

Choosing the Correct Steel Drum Manufacturer

To make sure you have the most beneficial outcome when purchasing Steel Drums from a Steel Drum Manufacturer, it is important to compare at least 4 or 5 Companies using our list of Steel Drums companies. Each Steel Drum Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Steel Drum company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Steel Drum businesses with the same quote.

55 Gallon Drums

55 Gallon Drums Floor Gratings

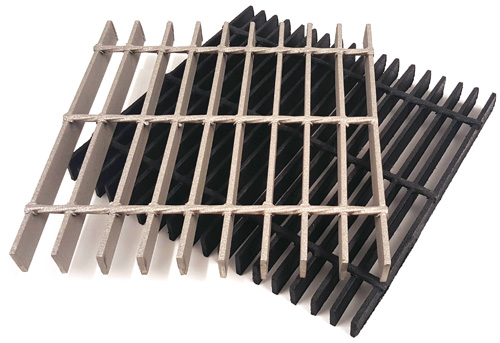

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services