Steel barrels, also known as 55-gallon drums, are commonly used in various industries for their durability, reusability, and cost-effectiveness. From industrial use to food and beverage storage, steel barrels play a vital role in modern society. In this article, we will explore the process of creating steel barrels, discuss their variations, benefits, and highlight their applications in different industries. Read More…

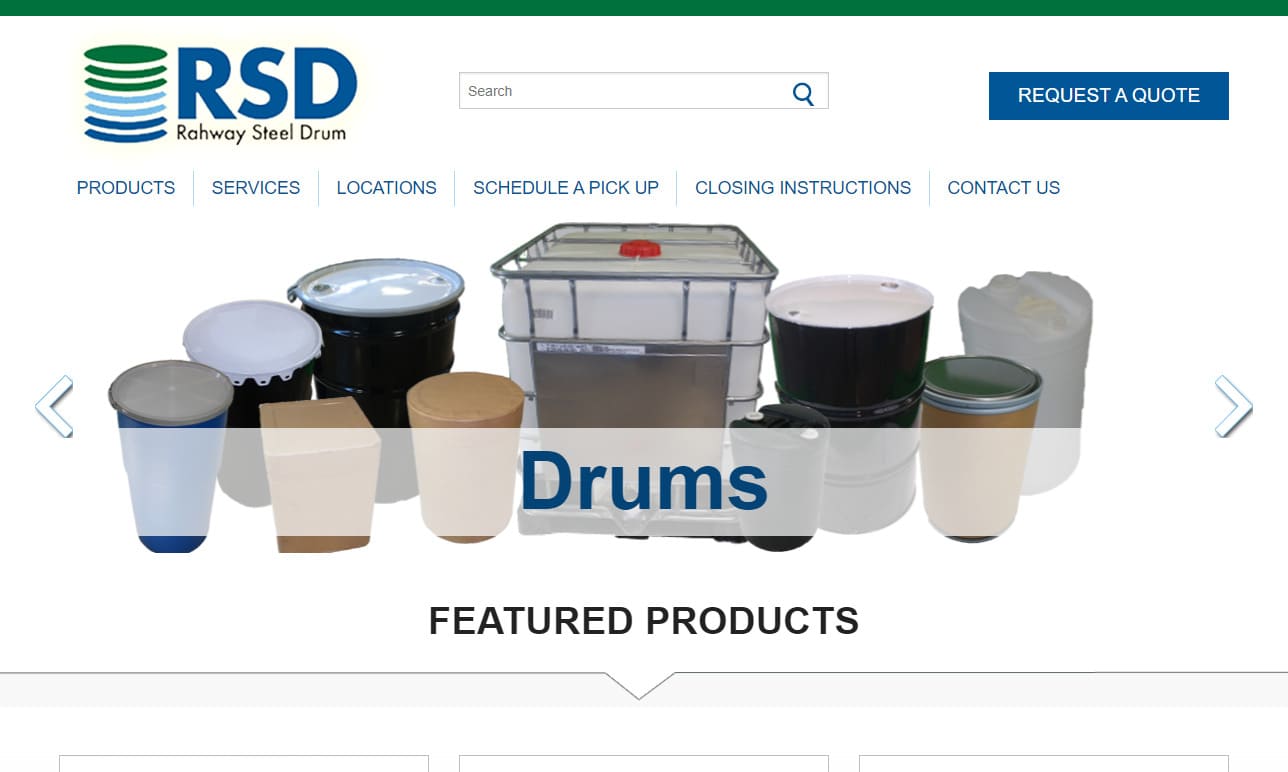

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

At O'Bryan Barrel Co., Inc., we take pride in our role as a leading provider of high-quality 55-gallon drums. Our dedication to excellence is evident in every aspect of our operations, from the materials we select to the craftsmanship of our products. We offer an extensive range of 55-gallon drums designed to meet various industrial needs, ensuring reliability and durability for our clients.

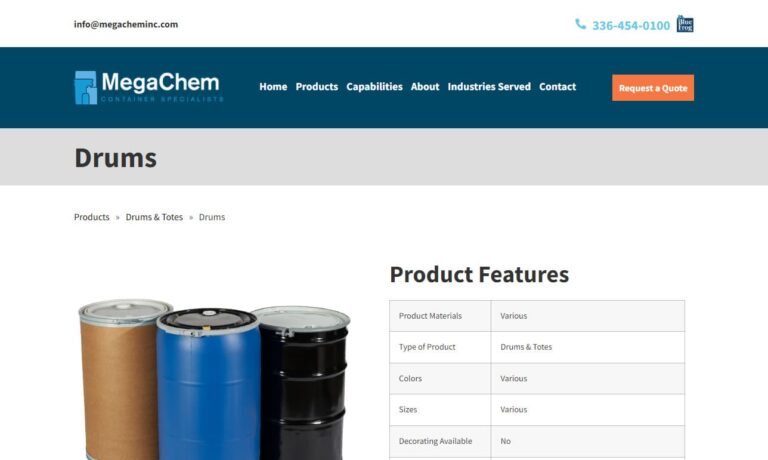

At MegaChem, Inc., we pride ourselves on being a leading provider of high-quality 55-gallon drums tailored to meet diverse industrial needs. Our extensive experience and innovative approach allow us to deliver products that excel in durability and reliability. We specialize in manufacturing and supplying drums that are crafted to withstand the rigorous demands of various industries, including...

House of Cans specializes in distributing plastic containers— bottles, drums, jars, jugs, and pails plus snap-lock and pry-off containers. We also offer plastic lids and shipping accessories. We offer our customers unrivaled customer service and high quality products. Our team is dedicated to advancing our company and creating innovative strategies and solutions.

More Steel Barrel Manufacturers

Creating Steel Barrels

Steel barrels are typically created through a process called drum rolling. First, flat sheets of steel are cut into circles, which are then molded into the shape of a barrel using a press. The two ends of the barrel are then sealed with lids, and a ring is placed around the barrel to hold it together.

Variations of Steel Barrel Designs

There are several variations of steel barrels that can be created based on the intended use, including:

Open Head Steel Barrels

Open head steel barrels, also known as removable head drums, have a removable lid that allows for easy access to the contents of the drum. The lid is typically held in place with a ring clamp, which can be removed to access the contents. Open head steel barrels are commonly used for the storage and transport of dry goods, chemicals, and hazardous materials. They can also be used for the storage of liquids, although they are not ideal for liquids that need to be completely sealed to prevent spills or leaks.

Open head steel barrels can be customized with different types of fittings and closures to meet specific requirements. For example, a bung closure can be added to allow for easy filling and dispensing of liquids. Open head steel barrels can also be fitted with different types of liners to prevent contamination and make cleaning easier.

Tight Head Steel Barrels

Tight head steel barrels, also known as closed head drums, have a permanently sealed top with only two small openings: one for filling and one for dispensing. Tight head steel barrels are ideal for the storage and transport of liquids, as they are completely sealed to prevent spills and leaks. Tight head steel barrels are commonly used in the oil and gas industry, as well as in the transportation of hazardous materials.

Tight head steel barrels can be customized with different types of closures and fittings to meet specific requirements. For example, a threaded bung closure can be added to allow for easy filling and dispensing of liquids. Tight head steel barrels can also be fitted with different types of linings, such as epoxy or phenolic coatings, to prevent corrosion and contamination.

Salvage Drums

Salvage drums are designed to contain damaged or leaking containers. These drums are typically made from heavier gauge steel and have thicker walls to prevent leaks and spills. Salvage drums also have special closures and fittings to prevent leaks and are often required by law for the safe transportation and disposal of hazardous waste.

Salvage drums can be customized with different types of fittings and closures to meet specific requirements. For example, a bung closure can be added to allow for easy filling and dispensing of liquids. Salvage drums can also be fitted with different types of liners to prevent contamination and make cleaning easier.

In summary, open head, tight head, and salvage drums all have unique designs that make them ideal for specific applications. Customizable closures, fittings, and linings allow for even more customization to fit specific needs.

Considerations Regarding Steel Barrels

While steel barrels have many benefits, there are also some considerations. One of the main concerns is their environmental impact. Steel barrels can be difficult to recycle, leading to excess waste. Additionally, if the barrels are not handled properly, they can leak or become contaminated, leading to potential health hazards. Furthermore, steel barrels have limitations when it comes to storage and transportation. Due to their size and weight, they may not be suitable for certain applications, and their contents must be carefully monitored to prevent spills or leaks.

Benefits of Steel Barrels

Despite these considerations, steel barrels have many benefits that make them a popular choice in various industries. For one, they are extremely durable and can withstand harsh conditions. Steel barrels can be used multiple times, making them a cost-effective solution for long-term storage and transportation needs. Steel barrels are also versatile and can be used to store a variety of materials, including liquids, solids, and hazardous waste. They are easy to clean and maintain, and can be customized to meet specific needs.

Applications of Steel Barrels

The benefits of steel barrels makes them ideal for a wide range of applications, including:

Dry Goods

Steel barrels are commonly used for the storage and transport of dry goods such as grains, powders, and small parts. Open head steel barrels are typically used for dry goods, as they allow for easy access and loading. Dry goods can also be stored in fiber drums, which provide a lighter weight and lower cost alternative to steel barrels.

Chemicals

Steel barrels are commonly used for the storage and transport of chemicals, including hazardous and non-hazardous materials. Open head steel barrels are typically used for chemicals, as they allow for easy access and loading. However, tight head steel barrels may also be used for hazardous chemicals, as they provide a completely sealed environment to prevent spills and leaks.

Hazardous Materials

Steel barrels are commonly used for the storage and transport of hazardous materials, including chemicals, fuels, and other dangerous goods. Salvage drums may be required for the safe transport and disposal of hazardous materials that may leak or spill during transport. Steel barrels can be fitted with different types of liners and coatings to prevent corrosion and contamination from hazardous materials.

Liquids

Steel barrels are commonly used for the storage and transport of liquids, including water, oils, and chemicals. Tight head steel barrels are typically used for liquids, as they provide a completely sealed environment to prevent spills and leaks. Steel barrels can be fitted with different types of closures, such as bung closures, to allow for easy filling and dispensing of liquids. They can also be fitted with different types of linings, such as epoxy or phenolic coatings, to prevent corrosion and contamination.

Gas or Oil

Steel barrels are commonly used in the oil and gas industry for the storage and transport of fuels, lubricants, and other petroleum products. Tight head steel barrels are typically used for oil and gas, as they provide a completely sealed environment to prevent spills and leaks. Steel barrels can also be fitted with different types of closures and fittings to allow for easy filling and dispensing of oil and gas products. They can also be fitted with different types of linings, such as epoxy or phenolic coatings, to prevent corrosion and contamination.

In summary, steel barrels are used in a variety of applications across different industries. From dry goods to hazardous materials, steel barrels offer a reliable and versatile storage and transport solution for a wide range of materials. The customization options available for steel barrels allow them to be tailored to specific applications, ensuring safe and efficient handling of materials.

Choosing the Right Steel Barrel Supplier

To ensure you have the most beneficial outcome when purchasing steel barrels from a steel barrel supplier, it is important to compare several companies using our directory of steel barrel suppliers. Each steel barrel supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each steel barrel business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple steel barrel companies with the same form.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services