Reconditioned drums are industrial containers that have been utilized for one application and then refurbished to fit the needs of another application after they have been utilized fully for their original application. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

We specialize in providing high-quality industrial packaging solutions, with a strong focus on 55-gallon drums for a wide range of applications. As a trusted partner in the packaging industry, we offer durable and reliable containers that meet the needs of various sectors, including chemicals, food processing, pharmaceuticals, and manufacturing. Our drums are designed for superior performance,...

We at Inmark, Inc. specialize in providing high-quality 55-gallon drums designed to meet the diverse storage and transportation needs of various industries. Our extensive expertise in industrial packaging allows us to offer solutions that prioritize durability, compliance, and efficiency. Whether handling hazardous materials, food-grade products, or general industrial goods, we ensure that our...

At Krook Container, Inc., we specialize in providing high-quality 55-gallon drums designed to meet the diverse needs of industries ranging from manufacturing and chemical processing to food and pharmaceuticals. Our extensive selection includes steel, plastic, and fiber drums, each engineered for durability, reliability, and compliance with industry standards.

More Reconditioned Drum Manufacturers

This form of drum is often much cheaper, as is typically the case with buying used products, but they also offer virtually the same advantages of purchasing brand new industrial containers for your project or job. Depending on your application there may be certain standards that you have to adhere to when shipping, especially if you are working with a dangerous or hazardous material. Be sure to check with the necessary officials on what these standards are and check with your reconditioned drum manufacturer to ensure that these standards are met before purchasing your order of drums.

There are two main categories or types of industrial drums, one is an open top drum and the other is a welded top drum. Open top drums have a removable lid to allow for easy access to the stored contents, and these are more commonly used for storage than shipping. Welded top drums, on the other hand, have their lid welded on to keep the contents from leaking or spilling, so these are typically used for shipping purposes or for more permanent storage. These two types of drums can be made from a number of different materials such as steel, plastics, paperboard, or a number of other metals depending on your application and requirements.

The manufacturing process is also heavily dependent on your applications needs and the material that is being used. For example if your application requires a plastic open top drum the injection blow molding process is typically utilized in order to achieve the right specifications. On the other hand metal drums are commonly manufactured from cold-rolled steel sheets that are then welded together and forged on a stamping press into their final shape.

Fortunately, with reconditioned drums, the manufacturing process is not quite as important, it still plays a part and is good information to know, but typically you will be able to evaluate the final product before your purchase to ensure that the right materials were used, the barrel was manufactured correctly, and that it has properly been restored since its previous use.

The best way to ensure that you receive a top of the line reconditioned drum is to work with an experienced drum manufacturer that has the right tools and knowledge to provide you with a reconditioned drum that will fit your needs and requirements.

55 Gallon Drums

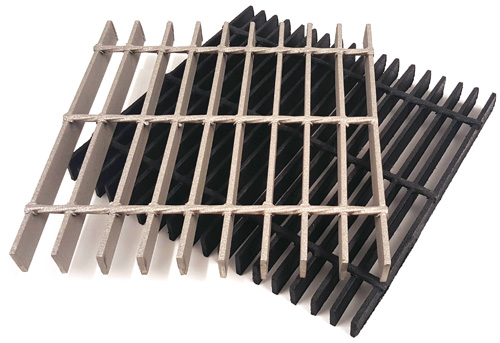

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

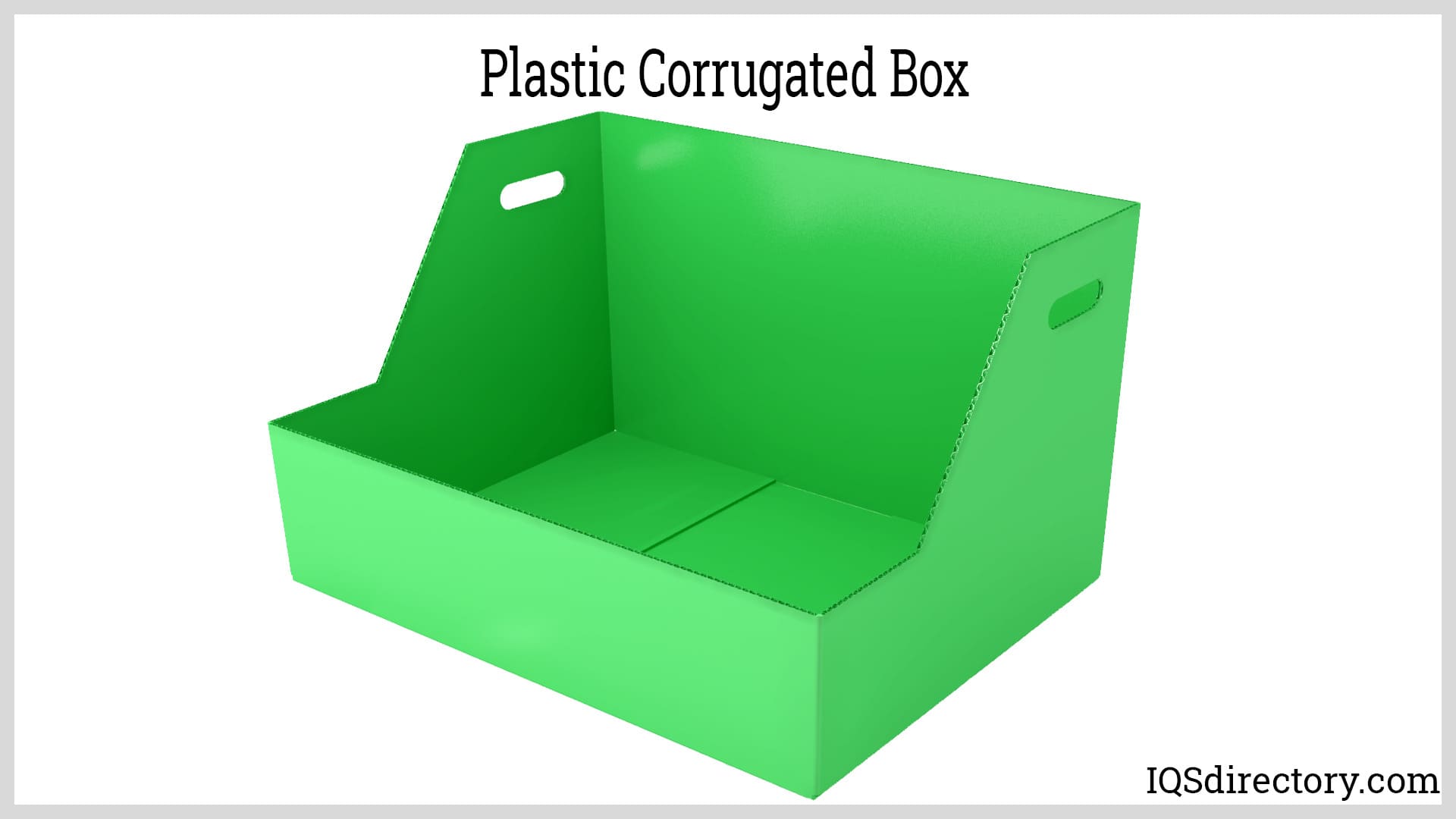

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services