Plastic barrels are spherical drums molded from high-density polyethylene (HDPE). Numerous hazardous items can be stored in plastic barrel drums. These drums are made to properly store and transport materials that must not leak. To seal any hazardous substance, these containers can be paired with sorbents (materials used to absorb liquids and gasses) to avoid leaks. These plastic barrels can also be used for shipping/storing other goods like food, beverages, oils etc. Plastic barrel drums work well as spill containment containers in spill-cleaning scenarios. They are used extensively in both residential and business settings for this purpose. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

At U.S. Plastic Corp., we provide high-quality 55-gallon drums designed to meet the rigorous demands of various industries. Our selection includes a variety of plastics, offering durability, chemical resistance, and compliance with industry standards for safe storage and transportation of liquids, solids, and hazardous materials. With a commitment to quality and customer satisfaction, we deliver...

We specialize in providing high-quality industrial packaging solutions, with a strong focus on 55-gallon drums for a wide range of applications. As a trusted partner in the packaging industry, we offer durable and reliable containers that meet the needs of various sectors, including chemicals, food processing, pharmaceuticals, and manufacturing. Our drums are designed for superior performance,...

We at Inmark, Inc. specialize in providing high-quality 55-gallon drums designed to meet the diverse storage and transportation needs of various industries. Our extensive expertise in industrial packaging allows us to offer solutions that prioritize durability, compliance, and efficiency. Whether handling hazardous materials, food-grade products, or general industrial goods, we ensure that our...

At Krook Container, Inc., we specialize in providing high-quality 55-gallon drums designed to meet the diverse needs of industries ranging from manufacturing and chemical processing to food and pharmaceuticals. Our extensive selection includes steel, plastic, and fiber drums, each engineered for durability, reliability, and compliance with industry standards.

More Plastic Barrel Manufacturers

How Plastic Barrels are Made

The selection of the appropriate high-density polymer, which may be low density for some types of barrels, is the first step in the fabrication of plastic barrels. The polymers for barrels begin as resin or pellets, which can be made from recycled plastic or freshly generated resin from the resin manufacturing process, depending on the type of barrel. Rotational molding, injection, and injection blow molding are the three techniques utilized to create plastic barrels, with injection blow molding being the most popular and effective. Resin pellets are heated up before being placed inside the mold cavity during the blow molding and injection molding procedures. Resin powder is melted in the heated mold during rotational molding.

Rotational Molding Process

Rotational molding begins with resin powder, which is neither heated nor melted before being placed into the mold, in contrast to injection and blow molding. During processing, the powdered substance is heated in the mold. The purpose of rotational molding is to create hollow items using rigidly configured steel or aluminum molds. For simple removal of the drum at the conclusion of the rotational operation, the interior of the mold is preconditioned with a release agent. Draft angles, which are tapers on the drum, are another variation of the procedure that makes removal simple without the use of a release agent. To properly distribute the heated resin powder throughout the mold walls, the mold is sealed and rotated in two planes. The heated mold's inner surface is covered evenly with the particulate plastic material, which is fused in stages until the appropriate shape and wall thickness are obtained. The quantity of powder resin added to the mold affects the walls' thickness, strength, and endurance.

Blow Molding Process

The resin pellets are manually or automatically fed into the hopper, where they pass through the feed barrel and into an extruder. The pellets are heated in the extruder and then transported to the blow molding die. The pellets are heated and melted by heating elements that are mounted to the outside of the screw drive so that they may form into the parison (the molten material) for forming in the mold. The plastic extruder is a crucial component of the heating process because it evenly heats the pellets, ensuring that they all reach the same temperature in the barrel. In order to prevent mistakes and deformations in the finished plastic barrels, this is crucial. The extruder's product is fed into an open mold that has the shape of a plastic barrel. The die is divided into parts, which are pressed together pneumatically or hydraulically. With an aperture on top to allow compressed air to force the parison to the walls of the die, the bottom and top of the parison are sealed between the die halves. The parison is blown into the mold under intense pressure, driving it to the sides. The air pressure makes sure that the plaster is applied to the mold's surface evenly. The air's force dispels any worries about bubbles, faults, or imperfections in the finished product. Until the parison or freshly produced drum has cooled, the die is kept shut. Depending on the kind of polymer being utilized, the cooling procedure differs. The pneumatic or hydraulic motor pushes the die halves apart to make it simple to remove the finished drum.

Applications of Plastic Barrels

- Plastic barrels have been proved to be the safest and most dependable solution for storing chemicals out of all the available options. Since it requires careful planning and outstanding plastic materials, storing and containing hazardous and volatile chemicals is an extremely risky and difficult task. Exposure of dangerous compounds to the environment is one of the main issues with chemical storage. The ideal choice for protection from external environmental conditions, severe heat, and close proximity to other chemicals is well sealed rust and corrosion resistant plastic barrels.

- Wine was traditionally fermented and stored for many centuries in wooden barrels, which ultimately gave way to stainless steel barrels. The wine industry has discovered that using plastic drums for fermentation and product storage is more cost-effective since the introduction of FDA food grade plastic barrels. Drums made of polyethylene are preferred because they are highly durable and chemically resistant. Manufacturers have found that plastic is lighter, easier to handle, and less expensive to clean than other materials. Plastic drums are a flexible and high-quality alternative to the conventional wood cask and make for an excellent storage container.

Choosing the Right Plastic Barrel Manufacturer

To make sure you have the most constructive outcome when purchasing plastic barrels from a plastic barrel supplier, it is important to compare at least 4 or 5 suppliers using our list of plastic barrel manufacturers. Each plastic barrel supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each plastic barrel company website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple plastic barrel companies with the same form.

55 Gallon Drums

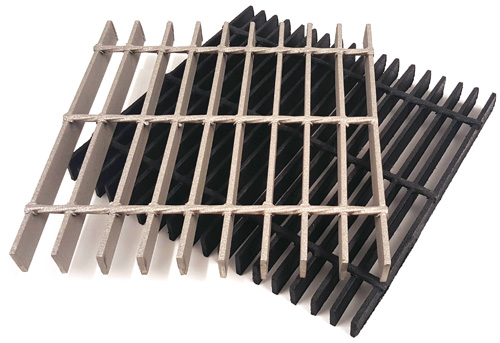

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

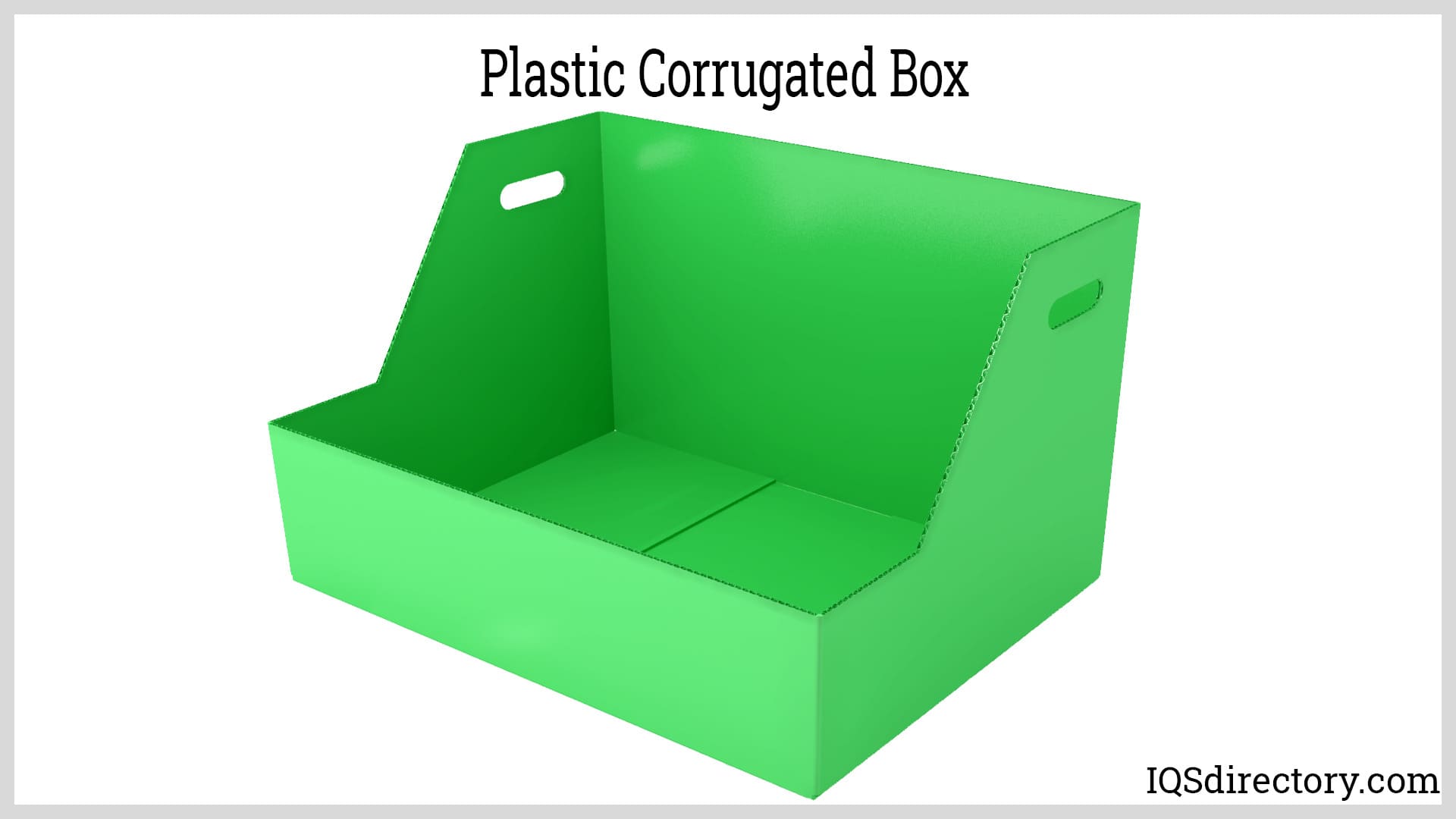

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services