Metal drums are used in many industries to store hazardous chemicals and all kinds of industrial goods. Metal drums are used for storing water, liquids, fuel, foods like grains and spices, oils, lubricants, solvents, chemicals, hazardous waste, and sand. Steel drums are the most versatile and popular among many commercial and industrial sectors; these are found in warehouses for the transportation of goods. Steel drums are cylindrical barrels specially designed to hold large quantities of liquids, semi-liquids, oils, chemicals, and food products. These are hard to wear, cost- effective, reusable, and long-lasting. Read More…

For over 60 years, Rahway Steel Drum Company has been a reliable supplier of 55 gallon drums and drum services. We supply containers from 1 quart to 330 gallons in quantities from 1 to over 100,000.

Container Distributors, Inc. is your one source for 55 gallon drums. We pride ourselves on our knowledgeable customer service staff, timely deliveries, and wide range of in-stock items.

Jakacki Bag & Barrel is the largest nationwide dealer for 55 gallon drums. Since 1942, we have sold 55 gallon drums of all assortments.

At O'Bryan Barrel Co., Inc., we take pride in our role as a leading provider of high-quality 55-gallon drums. Our dedication to excellence is evident in every aspect of our operations, from the materials we select to the craftsmanship of our products. We offer an extensive range of 55-gallon drums designed to meet various industrial needs, ensuring reliability and durability for our clients.

At MegaChem, Inc., we pride ourselves on being a leading provider of high-quality 55-gallon drums tailored to meet diverse industrial needs. Our extensive experience and innovative approach allow us to deliver products that excel in durability and reliability. We specialize in manufacturing and supplying drums that are crafted to withstand the rigorous demands of various industries, including...

House of Cans specializes in distributing plastic containers— bottles, drums, jars, jugs, and pails plus snap-lock and pry-off containers. We also offer plastic lids and shipping accessories. We offer our customers unrivaled customer service and high quality products. Our team is dedicated to advancing our company and creating innovative strategies and solutions.

More Metal Drum Manufacturers

There are two main types of steel drums, open-head and tight-head. The open-head metal drum has no covering, while the tight-head drum is sealed to store hazardous materials to minimize accidents. Both drums are fitted with nozzles and accessories for easy filling and emptying.

Types of Steel

The most commonly used material for manufacturing metal drums is steel, and any other metal is rarely used. Steel is widely used because of its wide range of properties that are best suitable for storing and transporting industrial products. Three types of steel are used for the fabrication of drums. These are:

Carbon Steel

- The more carbon content in the steel means it gets harder and stronger on heating.

- Carbon steel is an alloy of steel with a carbon content of 0.12% to 2%.

- Low-carbon steel is strong, tough, malleable, and ductile with low tensile strength.

- High-carbon steel works well with a heat treatment process, with no traces of impurities.

Stainless Steel

- Stainless steel is extremely durable and highly resistant to corrosion.

- Unlike regular steel, stainless steel does not corrode or rust with water because of the protective oxide film on it.

- Stainless steel has a recognizable luster with antibacterial properties.

- Stainless steel can be steam cleaned and sterilized, and it does not require to be painted or finished.

Cold-Rolled Steel

- Cold-rolled steels are smooth with better finishes and have an oily touch.

- Cold-rolled steels are harder and stronger than hot-rolled steel.

- This type of steel has easy formidability and tighter tolerance.

Each type of steel used for manufacturing metal drums is best suited for different applications. Carbon steel is used for handling and storing hazardous chemicals used in chemical processing, wastewater industries, etc. Stainless steel is best suited for sanitary applications and industries that require corrosion resistance, such as food and beverages. In addition, cold-rolled steel is used in industries that require high tensile strength, such as mining and defense.

Manufacturing Steel Drums

The manufacturing process of metal drums is a complex process consisting of several steps. Roll forming is the process that is used for making metal drums consisting of three basic steps:

Forming

Steel drums are produced by a plastic-forming method. This method is the best to make high-quality, high-strength workpieces with less material consumption and high productivity. Another special method for producing steel drums is roll forming. The steel body of the drum is placed on the mold, and processes like cutting and forming are done there. The roll forming cutting processes include sheet metal cutting, drum lid punching, blanking, and tapping.

Welding

The steel drum is welded with a seam welding machine which is a continuous method. It is an automatic method that uses two electrode wheels. The wheels are often disk-shaped and rotate when the material is passed through them. The material joints are melted with the help of current. These joints can be welded with the help of welding pressure. Seam welding results in an extremely durable weld.

Coating and Painting

Once the steel drums are formed, the next steps are the coating and painting procedures. Coating and painting are done to provide corrosion resistance and for aesthetic purposes. Cleaning is done before the coating, and the drums are rotated in the painting booth, where it is then sprayed. Finally, the drums are placed in an oven which dries the paint. After its drying, a code number, batch number or other information is inkjetted on these drums according to the client’s demand.

Applications of Metal Drums

- Metal drums are used by the transport and logistics industry for storing and transporting goods.

- The building and construction industry also uses metal drums to store building materials such as concrete or sand.

- The food and beverage industry also uses metal drums to store food items, spices, condiments, and many other products.

- The medical industry uses metal drums for safely storing equipment and other surgical products.

- Other industries like wastewater, chemical, and fuel processors use metal drums for storing hazardous materials.

Choosing the Right Metal Drum Manufacturer

To make sure you have the most positive outcome when purchasing metal drums from a metal drum manufacturer, it’s important to compare at least 4 suppliers using our metal drum directory. Each metal drum supplier has a business profile page which highlights their areas of experience and capabilities and has a contact form to directly communicate with the manufacturer for more information or request a quote. Review each metal drum company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple metal drum companies with the same quote.

55 Gallon Drums

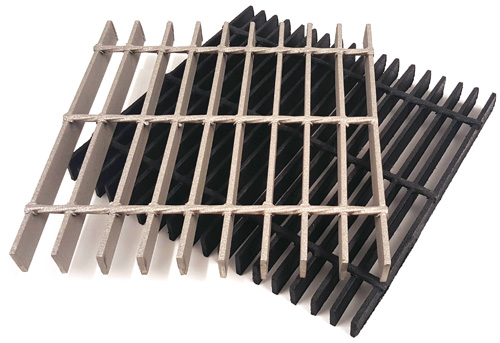

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services